UC3M patents a new design for a soft robotic joint that is more adaptable and robust

2/6/25

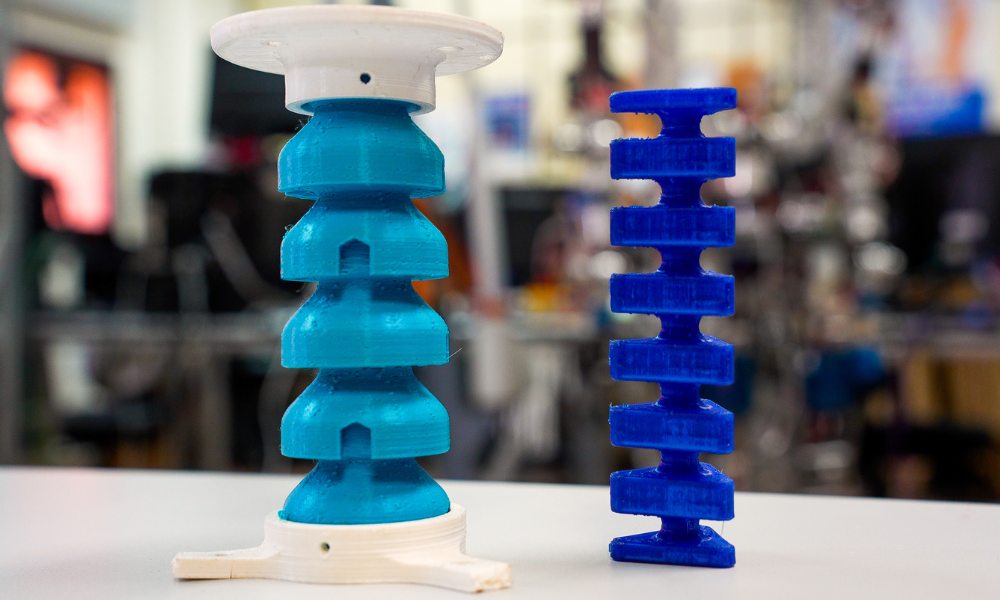

Researchers at Universidad Carlos III de Madrid (UC3M) have developed a new soft joint model for robots with an asymmetrical triangular structure and an extremely thin central column. This breakthrough, recently patented, allows for versatility of movement, adaptability and safety, and will have a major impact in the field of robotics.

“The main feature of this new design is that it allows greater bending angles to be achieved with less force, providing the robots with great versatility and adaptability of movement,” explains Concha Monje, professor in the UC3M Department of Systems Engineering and Automation and principal researcher on the SOFIA project. “In addition, by introducing asymmetry in the design, the joint is structurally blocked when bending limits imposed by the design itself are reached, which prevents the joint material from breaking or exceeding its elastic limit and provides greater operational protection for the robots,” she adds.

Keeping with the theme of safety, the researcher points out that the flexible material from which the joint is made facilitates the absorption of any impacts that the robots may cause during the performance of their tasks, resulting in increased safety in their interactions with humans. This flexibility also allows for operations to be carried out in confined environments or in handling situations that require greater adaptability to the work environment. “And that's not all: this type of joint can function as an independent actuation module or connected with other joint modules to form a highly functional robotic handling chain,” says Concha Monje.

Another characteristic of the soft joint is that it bends with a constant curvature, which significantly simplifies its mathematical model. This facilitates the design of control systems that allow robust operation at a very low computational cost.

Finally, the researcher highlights the fact that the joint can be manufactured using standard 3D printers, with elastic materials that do not require a large investment, allowing for rapid and very economical manufacturing.

Currently, the UC3M RoboticsLab team is developing a robotic claw whose fingers feature the patented joint design. This allows it to grip objects with a high degree of dexterity, facilitated by the different contact surfaces with which the robotic arm can engage in order to attain said grip.

Referencia de la patente: C.A. Monje, C. Relaño, L.F. Nagua, S. Martínez, C. Balaguer, Eslabón para articulación blanda y articulación blanda que comprende dicho eslabón. P202030726. 19/06/2024. Universidad Carlos III de Madrid.

https://consultas2.oepm.es/InvenesWeb/detalle?referencia=P202030726

https://consultas2.oepm.es/ceo/jsp/busqueda/busqRapida.xhtml